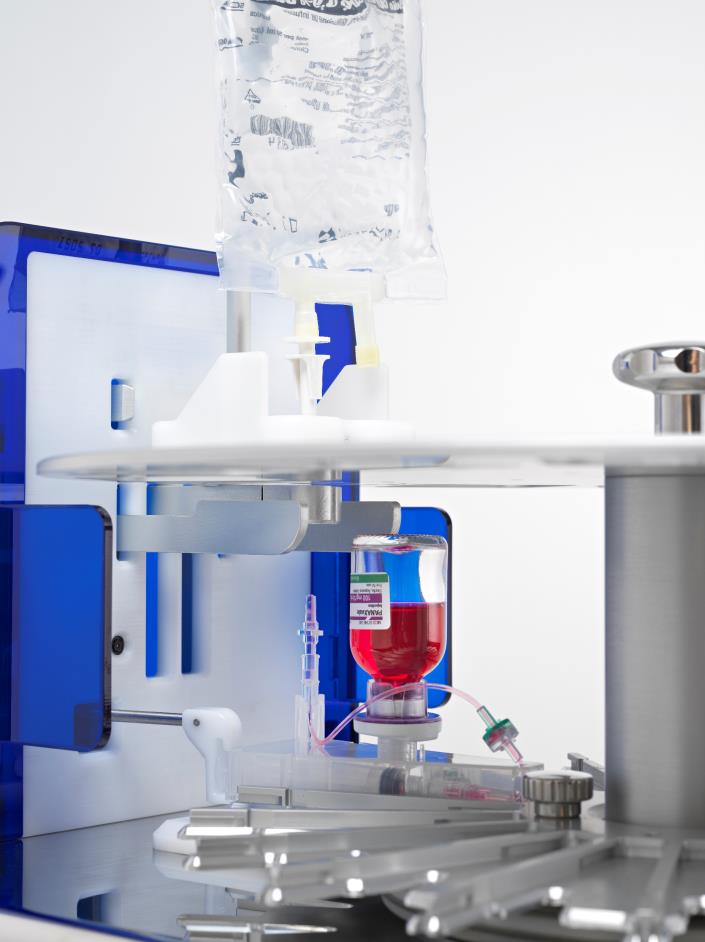

ChemoMaker+

Innovative technology for the preparation of patient-specific chemotherapy drugs.

What is ChemoMaker+?

It is an innovative system for the automated preparation of chemotherapy drugs that allows:

Make several preparations at the same time

Speed up setup times

Maintain high dosing accuracy

Reduce risks for operators and patients

- Table equipment 72x45x65cm

- Barcode + RFID

- Gravimetric balance

Main technical characteristics

- Liquid phase Chemotherapy drug preparation

- Table equipment

- Can be placed under an existing laminar flow hood

- Built-in gravimetric balance for better accuracy

- Double verification (Barcode + RFID)

- Up to 12 compounds and 16 drugs per batch

- Up to 30 compounds per hour

- Medicine vials up to 100 ml

- Multidose medication bags up to 1000 ml

Benefits

Security

- For patients: guarantees the sterility of the preparation and reduces the risk of cross contamination. Preparation errors are also reduced.

- For operators: they do not have to handle cytotoxic drugs.

Waste management

- Savings of 10% of the cost of the drug, reusing residual drugs.

- Waste management becomes faster, simpler and more precise.

Effectiveness

- Faster and more optimized preparation processes.

- Up to 12 preparations and 16 drugs per batch.

- Up to 30 preparations/hour.

- Reduction of preparation errors.

Precision

- Very high dosing precision.

- Thanks to the integrated real-time gravimetric control, an average error of 1% is guaranteed (EU Pharmacopoeia tolerates a 10% error).

Flexibility

- Desktop size and light weight.

- Quick installation: inserts directly into existing laminar flow cabinet.

- It does not require specific space or technical personnel.

Traceability

- Dual control system: barcode and patented smart cartridges with integrated RFID.

Advantages

Preparation 1 medicine at a time. 15-20 doses/h

15-20 doses/h

30 doses/h

Low. High risk to the health of operators

High

High

Risk of human error in preparation

Barcode

Bar code + RFID Integrated gravimetric scale

High personal expense. Two operators are needed during the entire process

High energy consumption (12kw/h)

Low energy consumption. Automated process, no operator required

They are discarded manually with risk for the operator

They are automatically discarded

Reuse of residual medicines. Savings of 10% of the cost of the drug

mean error 10%

mean error 5%

mean error < 1%

-

4 m3 > 1500 kg

2 m3 (72x45x65cm) 30kg

-

Complicated cleaning Scheduled maintenance only

Easy cleaning

AI software for predictive maintenance

-

High

40% cheaper

Complies with the Machinery Directive (2006/42/CE) and the EMC Directive (2014/30/UE)

Directive 2006/42/EC / Directive 2014/30/EU / IEC 61010-1:2010 / EN 61326-1:2013 / ETSI EN 301 489-1 V2.1.1 / ETSI EN 301 489-3 V2.1.1 / ETSI EN 301 489-17 V.3.1.1 / EN 62311:2008 / ETSI EN 300 328 V2.1.1 (§ 4.3.2.9 and 4.3.2.10) / ETSI EN 300 330 V2.1.1